Who We Are

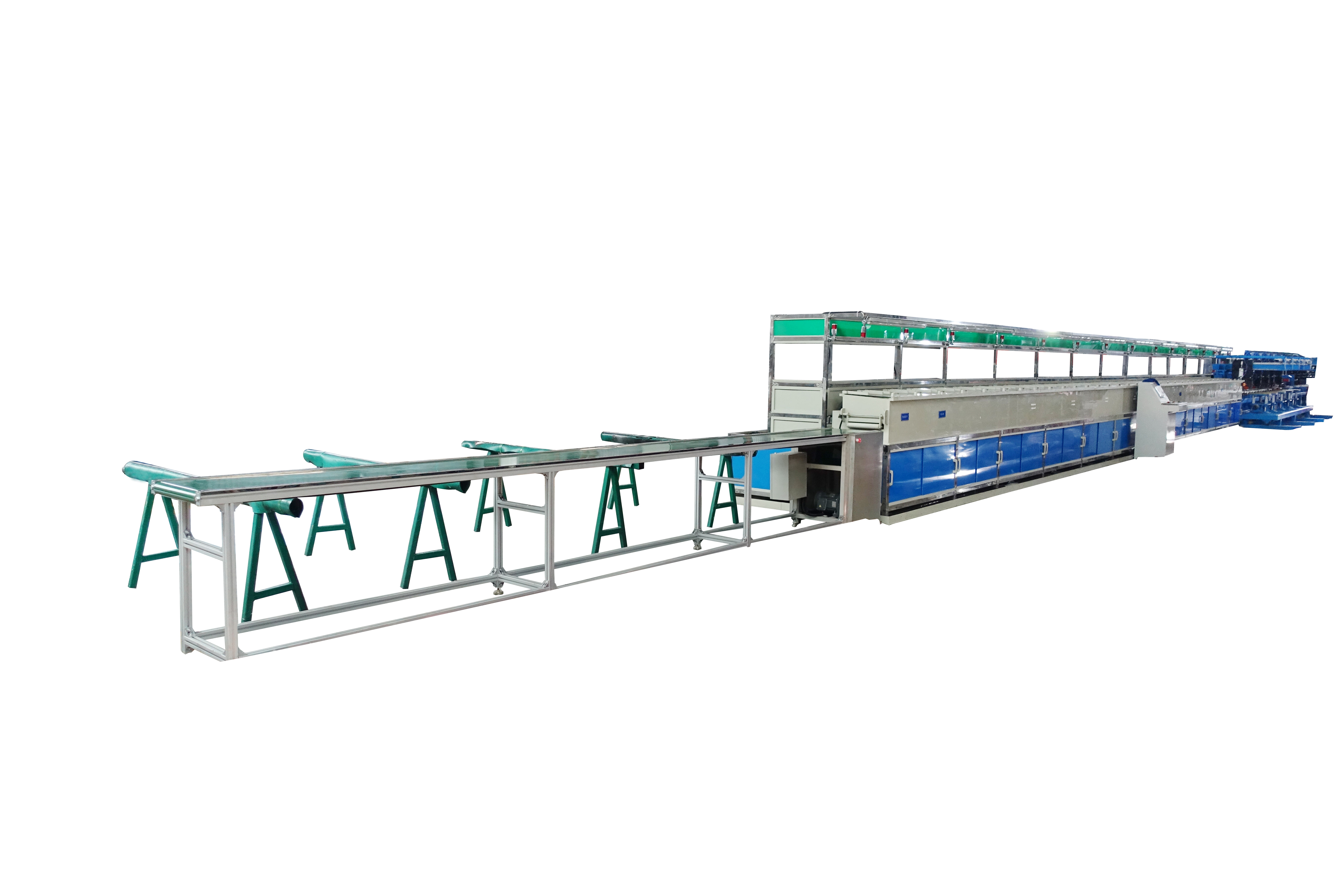

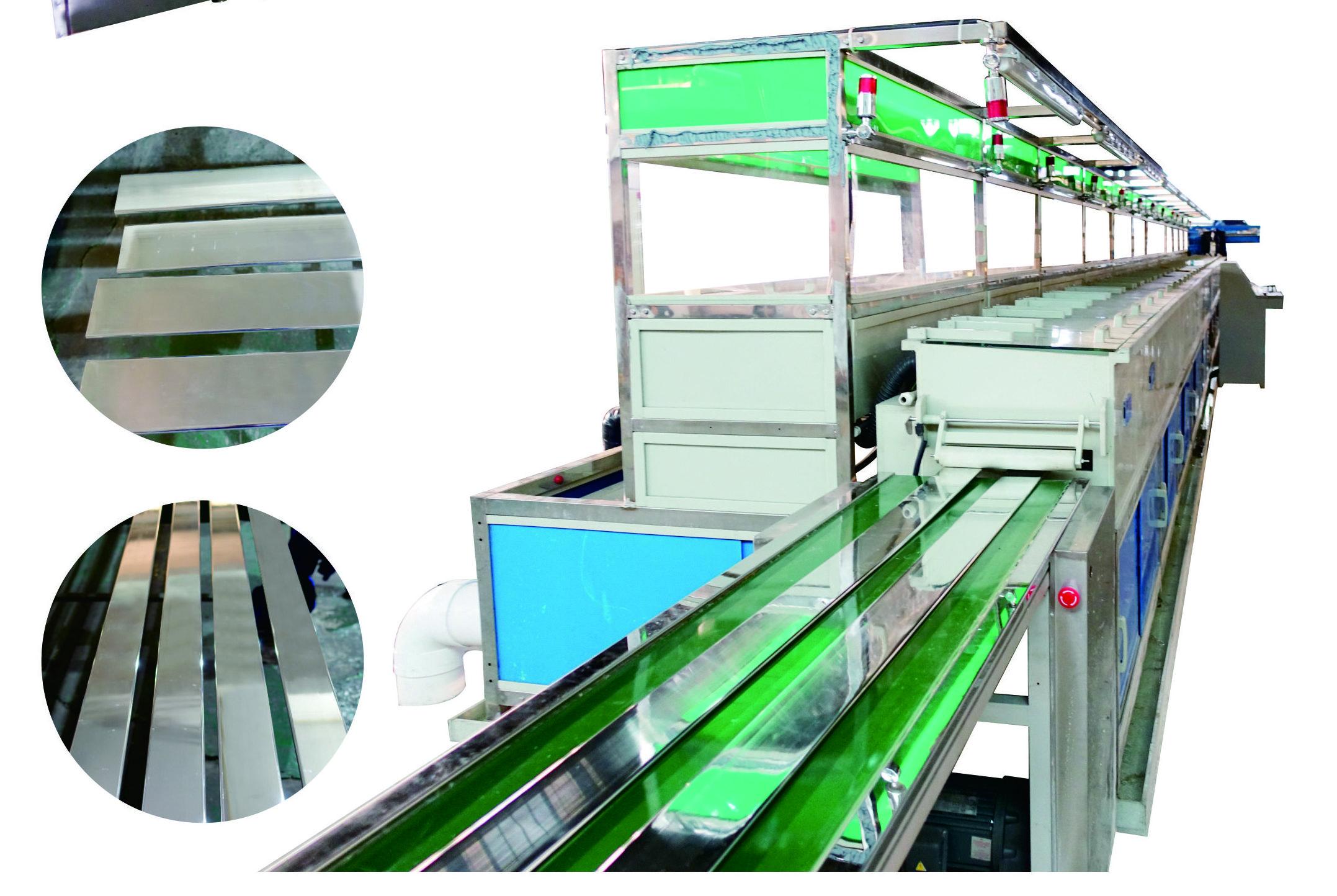

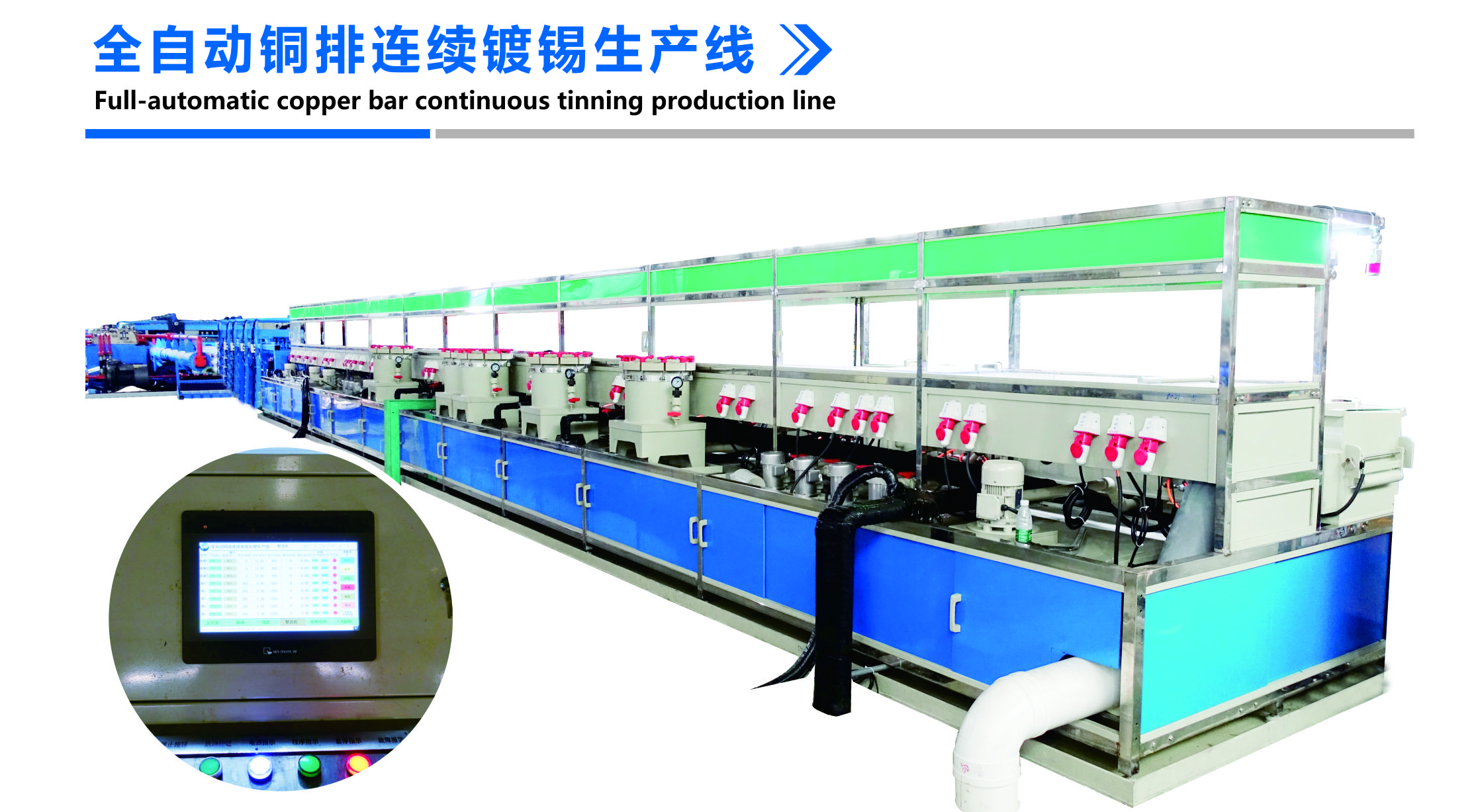

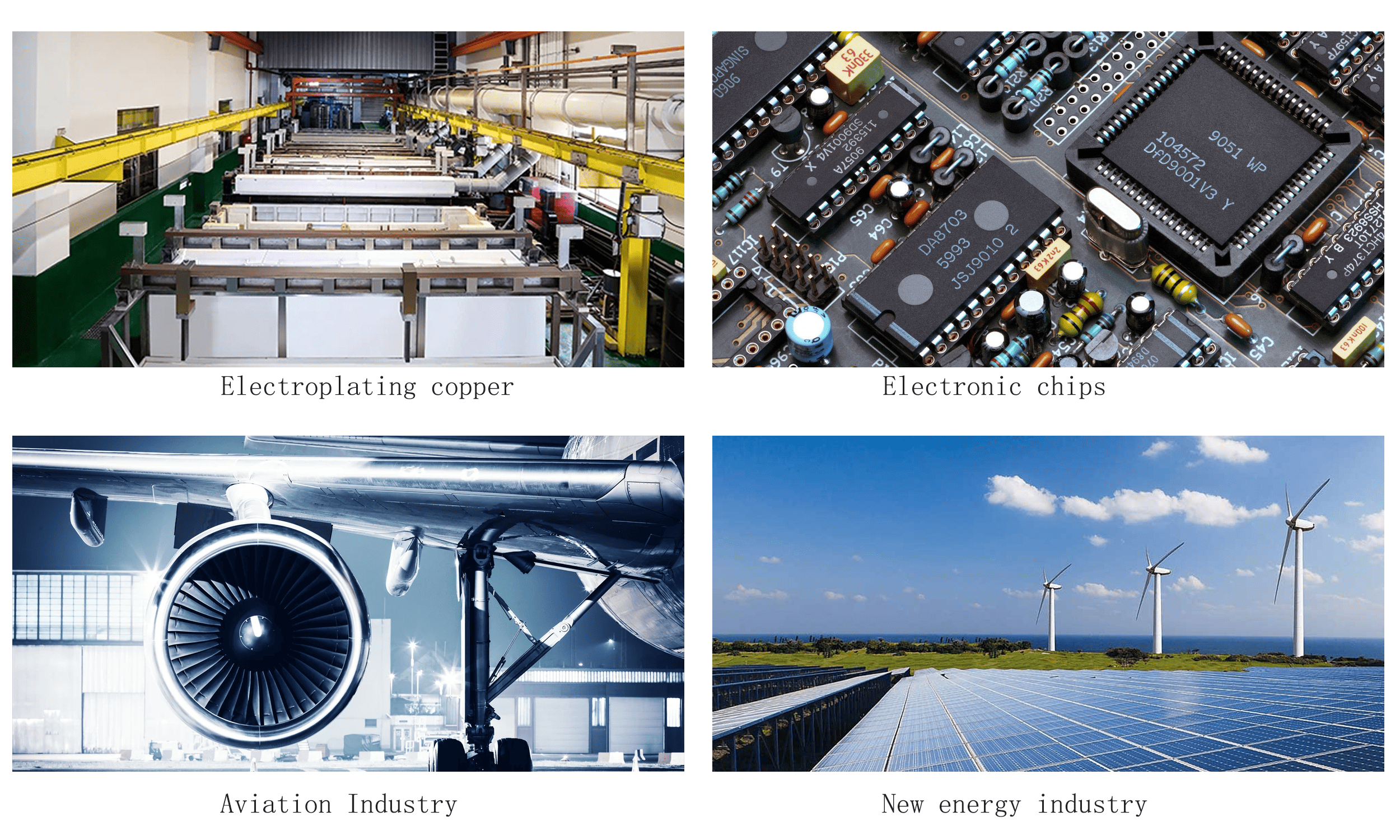

Guangdong Shunhong Technology Co., Ltd. is an innovative enterprise focused on R&D and production of electroplating equipment. Our professional technical team is committed to efficient and intelligent solutions for metal surface treatment.

- 10+ years of electroplating R&D experience

- Professional technical teams and engineers

- Patented, award-winning equipment